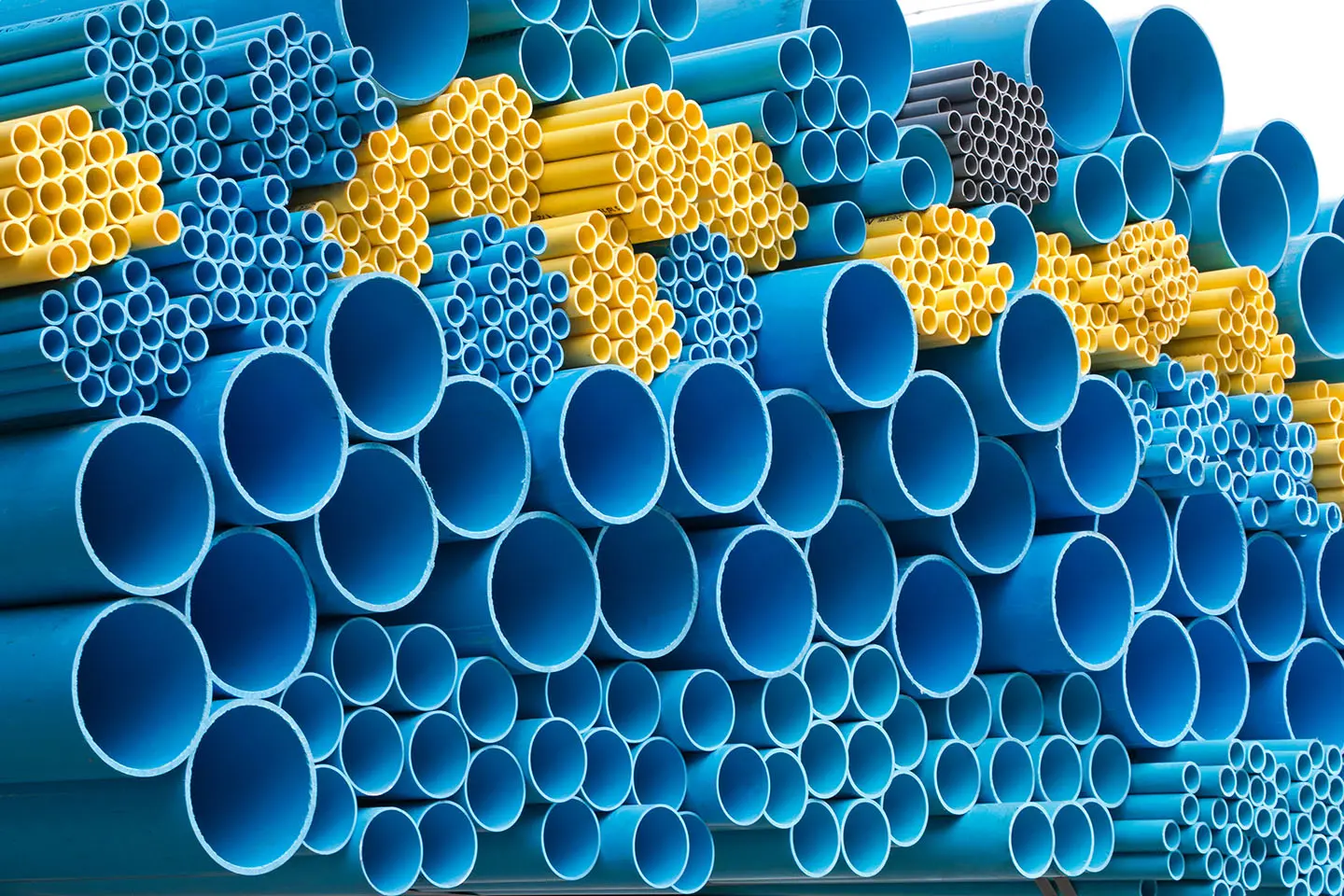

The Plastic (PVC), Rubber & Fiber Manufacturing Industry faces challenges such as manual processes, paperwork, siloed data, low OEE, and difficulties in focusing on manufacturing without digital automation. The absence of modern software increases technical debt and slows down progress.

The solution to these challenges is digital transformation through the implementation of Industry 4.0 technologies, such as use of a modern MES like IfElseCloud. Automating manual processes, eliminating paperwork, and implementing automated reports will lead to improved OEE, reduced downtime, and enhanced quality. The use of machine learning and artificial intelligence will provide insights into operations, enabling informed decision-making. Digitalizing manufacturing processes will attract a younger workforce and improve smart industry readiness.

Optimize operations from analog to digital with smart apps that digitize workflows, simplify communication, and enable effective collaboration, ensuring business stays ahead in today's fast-paced digital and modern MES landscapes.

Groundbreaking MES futuristic technologies merge with optimized processes to drive operational excellence, agility, and sustainable growth with our MES.

Create a connected digital cloud ecosystem, enabling real-time monitoring, and seamless MES integration across operations.

Take a critical look at the production processes, implementing strategic improvements to seamless workflows.

Leverage the power of digital data analytics to make informed decisions, optimize resource allocation with our digital platform.

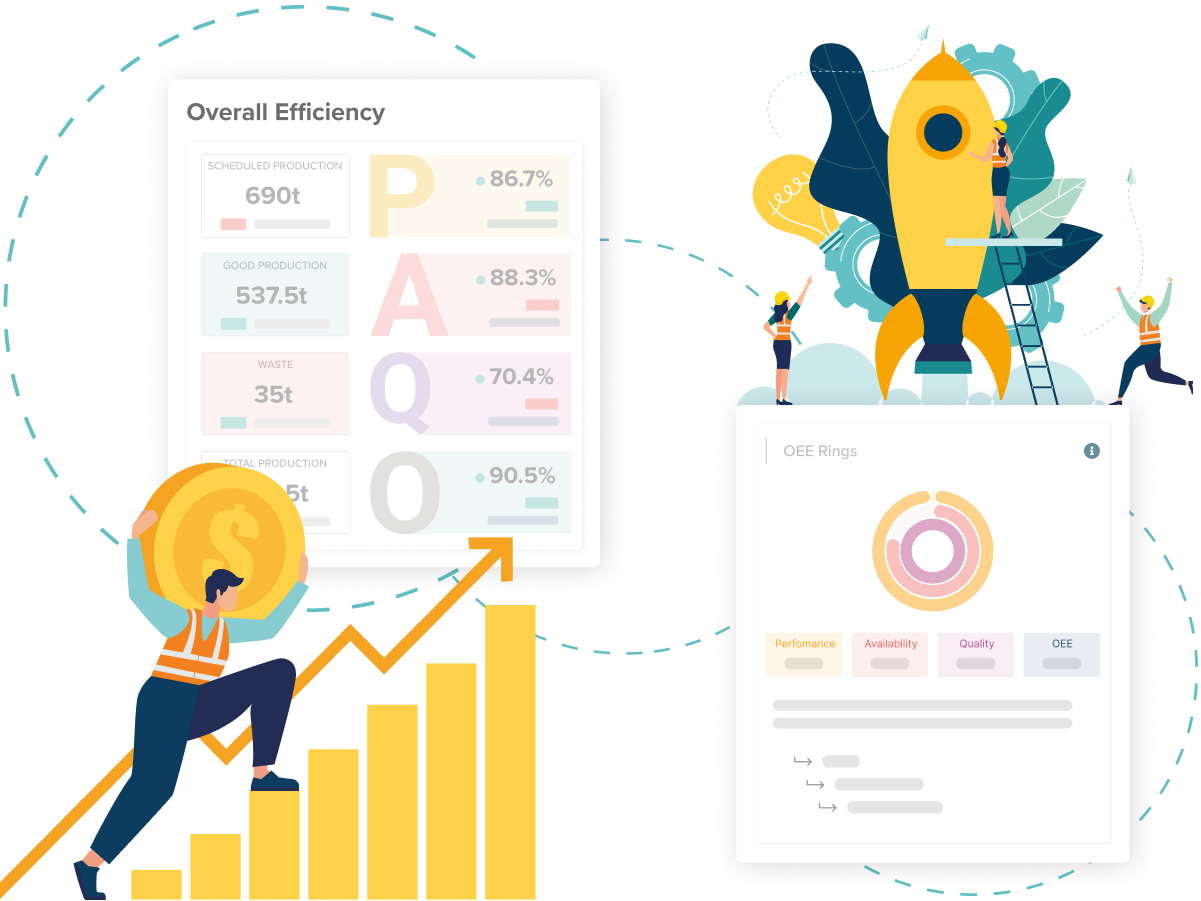

With the help of our modern MES, optimizing your operations for performance, availability, and quality, you can improve your bottom line, enhance your customer experience, and unlock new opportunities for growth

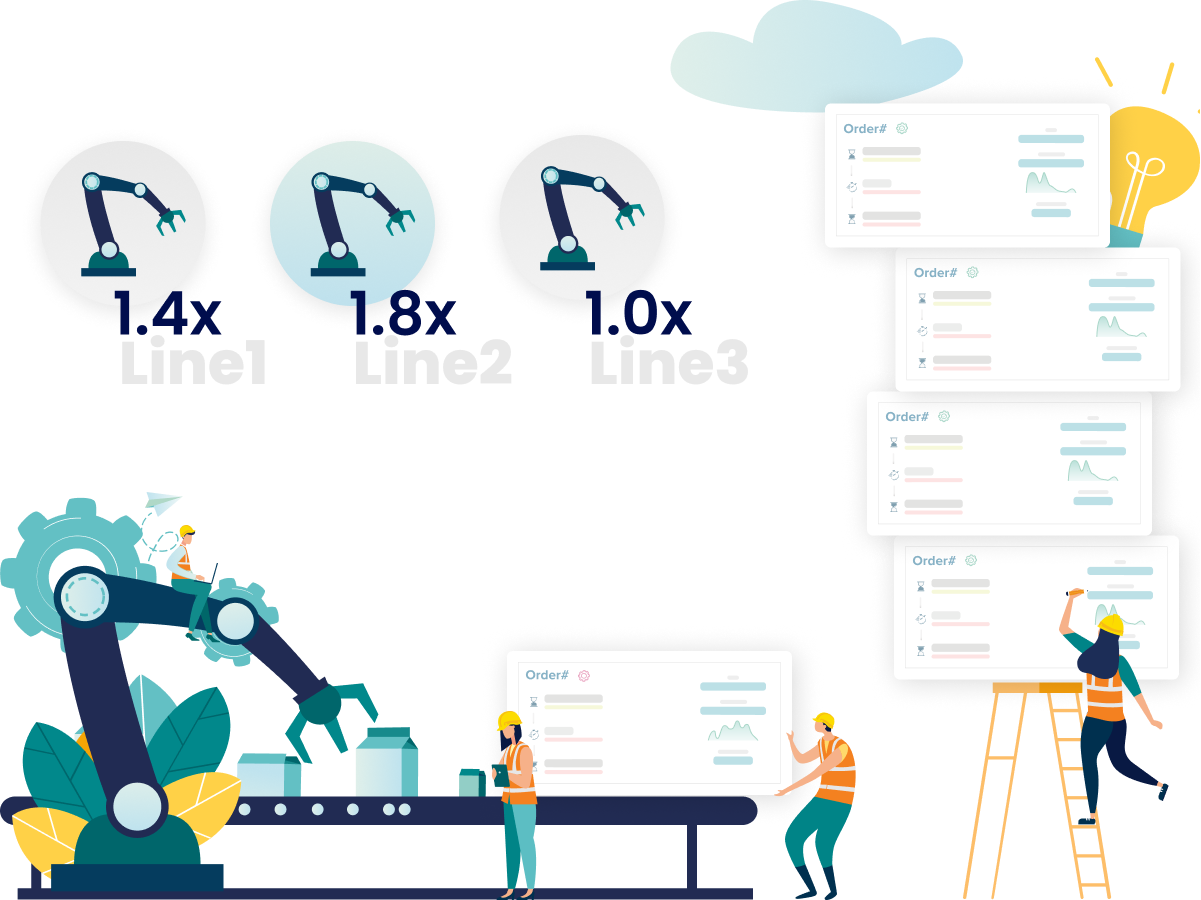

Modern MES line efficiency monitoring can improve productivity, enhance quality, and reduce costs. Adopt smart manufacturing.

Improve visibility into operations and enhance business performance with the MES production line dashboard.

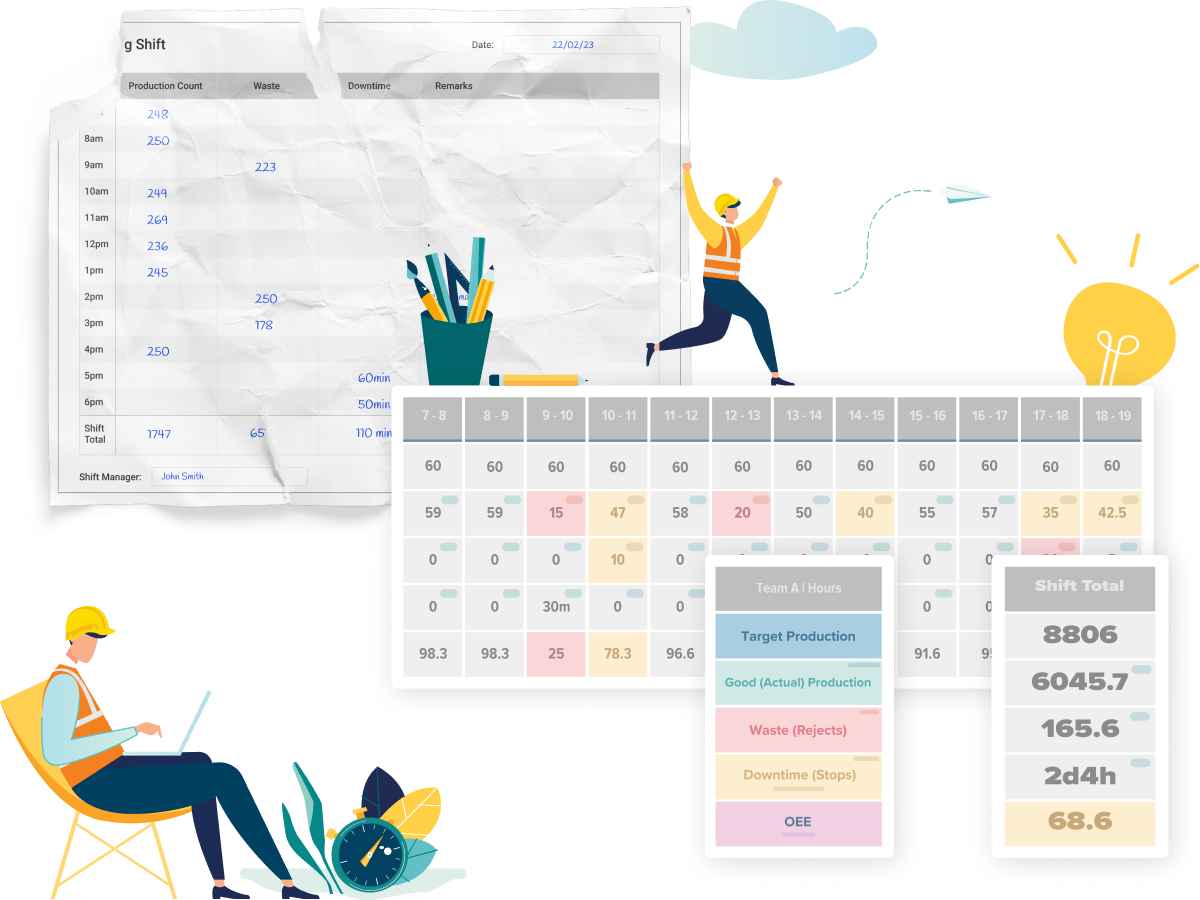

Enable real-time production pacing and scheduling on the shopfloor with an intuitive modern MES digital board.

Identify and address production failures swiftly with the MES failure reasons dashboard.

Younger workers are often more comfortable using technology, and by adopting our latest MES, create a more modern, dynamic workplace that attracts and retains top talent in plastic, rubber & fiber manufacturing industry.

Improve collaboration among , suppliers, team members and customers, leading to better outcomes with our modern paperless MES solutions.

A digital workplace that values teamwork, and innovation can build a culture that appeals to younger workers with the MES.

Stay ahead in manufacturing industries with a proactive outlook. Embrace innovation, automation, and digital transformation with our digital MES platform.

Offer mobile accessibility to align with the preferences of the younger generation. Drive productivity with an advanced MES.

By utilizing MTBF, MTTR, and MTTF insights, manufacturers can optimize maintenance activities, reduce equipment downtime, and improve asset longevity and they can do it with the help of our digital MES platform.

Drive operational excellence and improve ROI through modern MES and data-driven asset management strategies fueled by insightful metrics.

Assess equipment reliability, identify mean time between failures, potential issues, with our digital MES.

Reduce equipment downtime & identify MTTR with an advanced metrics, enabling swift resolution of issues

Identify the mean time of equipment failures and implement preventive measures to minimize downtime with our MES.

Adopt ML and AI in work order management, gain real-time visibility into equipment performance and take proactive measures to improve productivity with the help of our digital MES platform in plastic, rubber & fiber manufacturing industry.

Achieve optimal work order scheduling outcomes by leveraging digital manufacturing and data-driven approaches, enabling better resource allocation.

Enhance productivity through flexible work order visualization, enabling efficient task tracking and optimized operations.

Effortlessly schedule work orders with our digital transformation and data-driven insights, ensuring optimal task scheduling.

Reduce order fulfilment times, increase order accuracy, and improve overall customer satisfaction with ERP & E-Commerce.

Upgrade preventive maintenance activities, enhance asset management, and achieve operational excellence with the help of our advanced MES maintenance planning and scheduling in rubber & fiber, plastic (PVC) manufacturing industry.

Visualize your maintenance planning with clarity and ease, empowering you to efficiently allocate resources and optimize workflow management.

Optimize task coordination and workflow management with MES Gantt & Calendar views for work orders.

Enhance productivity with effortless recurring maintenance planning with our digital MES platform.

Simplify SOPs for breakdown maintenance, ensuring swift response with our digital MES.

Enhance decision-making capabilities with our modern digital platform for automated and real-time reporting, providing comprehensive insights into plastic, rubber & fiber manufacturing operations.

Improve bottom line with our modern paperless and no whiteboards platform, reducing costs associated with paper and manual processes.

Empower manufacturing operations teams with automated reporting, enabling data-driven decisions with our MES.

Identify opportunities for productivity, gain valuable insights for better business digital transformation planning.

Upgrade financial decisions with intuitive reporting interfaces, providing financial executives with actionable insights.

Unlock the power of collaboration with a central data hub, enabling teams to access real-time information, drive synergy, and achieve shared goals with our digital manufacturing executed systems.

Bid farewell to siloed data and embrace a unified approach, enabling seamless access and collaboration across your manufacturing industry.

Access project files and documents from a centralized platform, anytime, anywhere with the digital MES collaboration.

Eliminate the information silos and promote inclusivity by offering a solution that enables seamless data sharing.

Uncover the full potential of your team with a continuous feedback loop that empowers individual productivity.

Gain a competitive edge by leveraging your manufacturing data, extracting valuable insights that inform proactive and strategic decision-making in your Plastic(PVC), Rubber & Fiber manufacturing industry.

Upgrade operations with data-driven manufacturing decisions, leveraging analytics for continuous improvement with our digital platform.

Identify and address the root causes of issues, improving product quality and reducing downtime with our digital MES.

Gain visibility into production trends for data-driven decision-making, driving operational efficiency with an advanced MES.

Maximize profits by optimizing costs and minimizing losses with data-driven insights and smarter processes with our MES.

Take full control with a white-label MES platform that allows you to customize it to your Plastic, Rubber & Fiber industry branding, locale, and manufacturing processes with our digital manufacturing tool.

Personalize the MES platform to suit your manufacturing workflows, facilitating data integration, analysis, and actionable insights.

Evaluate OEE & key performance indicators to optimize processes, reduce waste, and increase productivity.

Personalize the digital MES platform with branded interfaces and localized language support.

Efficiently manage inventory, reduce waste, and minimize errors with customized SKUs and assets with our MES.

120+

With the help of our advanced MES data streaming technology delivers real-time data with minimal latency, ensuring up-to-date information.

Our advanced data analytics algorithms help identify and address inconsistencies in data, leading to accurate data.

IfElseCloud's advanced search capabilities enable teams to quickly find and access relevant data, reducing the impact of data silos.

Our digital MES keeps your data private and helps you track all of the data simultaneously, which helps trace data.

IfElseCloud enables organizations to compare their production processes to industry best practices, promoting process optimization.

Our advanced digital MES, enables dynamic production planning, allowing rapid adjustments to align with changing demand scenarios.

IfElseCloud's predictive maintenance features reduce downtime and improve production efficiency, supporting process optimization.

Our customizable digital dashboard enables organizations to monitor and manage production processes in real-time, identifying bottlenecks and inefficiencies quickly.

IfElseCloud's remote monitoring capabilities enable industries to monitor equipment health and maintenance activities from remote locations.

MES helps industries plan and execute tasks more efficiently, reduce downtime & identify bottlenecks in production.

IfElseCloud's root cause analysis capabilities enable industries to identify the underlying causes of waste and scrap, enabling targeted process improvement

Our reporting capabilities enable industries to generate financial reports that provide detailed information on production costs, facilitating cost tracking.

This capability enables manufacturing industries to develop innovative products and services, enhancing competitiveness and customer value.

MES enables industries to offer remote work options for senior managers, enhancing the attraction of a skilled workforce.

With the help of MES, industries can provide employees with flexible work arrangements and support work-life balance, which helps retain an experienced workforce.

Our MES's bottleneck prevention and talent retention enable industries to prevent bottlenecks, retain top talent, and enhance process efficiency.

Our MES enables the creation of teams of employees from different departments, enhancing collaboration. Teams can contribute to other departments using data analytics that gives them in-depth knowledge of other manufacturing areas.

Our digital MES, enables industries to manage workflows and tasks effectively, reducing manual labor costs.

IfElseCloud's capabilities enable manufacturing industries to evaluate the costs and benefits of different production processes, facilitating strategic decision-making.

IfElseCloud's data visualization capabilities enable organizations to visualize data and make informed decisions quickly and reduce slow decision-making.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for the Plastic (PVC), Rubber & Fiber industry digitalize your processes and increase efficiency, providing you with a competitive edge.

Contact us to learn how we can benefit your Plastic (PVC), Rubber & Fiber manufacturing operations.